The oil as well as gas sector relies greatly on specific tools to perform drilling, workover, and refinery operations. From boring tools to pressure control devices, these necessary tools play a vital role in removing, processing, and refining oil resources. In Single-stage Centrifugal Pump , we will check out several of the key tools used in the market and their value in making certain smooth operations.

Exploration devices are basic in the exploration as well as removal of oil and gas reserves. They consist of drill bits, pierce collars, piercing jars, and stabilizers, to name a few. Drill little bits, for instance, are responsible for cutting through various rock developments throughout the exploration procedure. Advanced designs as well as materials, such as polycrystalline diamond compact (PDC) and diamond-enhanced inserts, have actually dramatically improved their durability and also efficiency, leading to extra efficient drilling operations. Pierce collars give weight and stiffness to the drill string, enabling better control and also penetration. Drilling containers help release a stuck drill string by developing an effect pressure to launch it. Stabilizers ensure the security of the borehole by reducing vibration as well as preserving trajectory control.

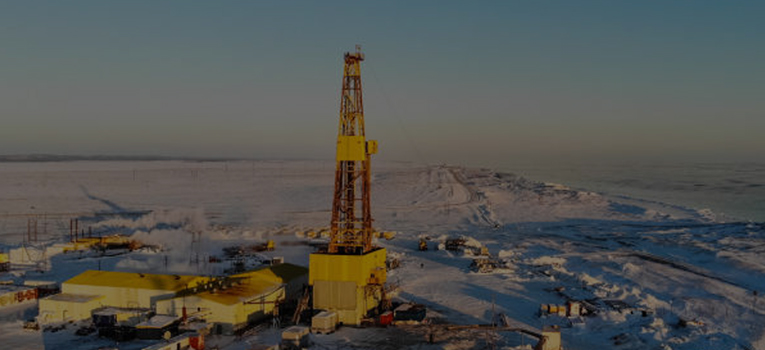

Exploration and also workover tools include a variety of machinery called for throughout the exploration and workover stages. Boring rigs are huge structures that house the boring tools and supply support for the exploration procedures. Well control systems, including blowout preventers (BOPs) as well as choke manifolds, are important for keeping safe drilling as well as manufacturing procedures.

Oil refinery devices is essential in transforming crude oil into functional items, such as gasoline, diesel, and jet gas. Secret equipment consists of distillation towers, catalytic converters, hydrotreaters, and fractionating columns. Distillation towers different crude oil into different parts based on their boiling factors.

Stress control tools is essential for preserving safe drilling and manufacturing operations. In addition to blowout preventers, stress control tools consists of choke shutoffs, eliminate shutoffs, as well as pressure alleviation systems. Choke valves control the circulation price of liquids and also gases during exploration, while kill shutoffs supply a means to quit flow in situation of emergencies. Pressure relief systems, such as safety valve and tear discs, are developed to launch excess stress and prevent devices damages or failure. These systems interact to preserve safe stress levels and also make certain operational honesty.

During exploration procedures, piercing fluids carry pierced cuttings to the surface for separation and disposal. They get rid of unwanted solids from the boring mud, permitting it to be recycled, lowering ecological influence and functional expenses. Solids manage devices consists of shale shakers, centrifuges, desanders, desilters, as well as mud cleansers.

Centrifugal pumps are widely utilized in the oil and also gas sector for different applications, consisting of drilling, manufacturing, and also refinery procedures. These pumps offer the necessary pressure to circulate drilling mud, transfer fluids between various stages of refining, and also keep the circulation of fluids throughout the system.

The oil as well as gas industry greatly relies on specific devices to execute boring, workover, and refinery procedures efficiently. From drilling tools and also workover gears to pressure control devices and warmth exchangers, each part plays an essential duty in making certain safe as well as effective procedures. By investing in innovative equipment and technologies, the sector remains to improve its capacities, enhance safety and security criteria, as well as optimize the extraction as well as refining of important petroleum resources. These vital devices make it possible for the market to fulfill growing energy demands while lessening ecological impact and also making the most of operational efficiency.